Glass breakage in the tempering furnace is something that we all want to avoid. In this #AskGlaston episode, we are looking at the factors that can lead to the breakage of thick glass in a radiation furnace. The other question refers to the difference of heat-strengthened and tempered glass.

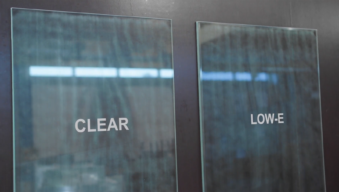

This latest #AskGlaston episode will cover two questions devoted to the issues of improving the production of special coated and patterned glass. 1. How can you improve the continuous production of 8 mm Low-E triple-layer silver-coated glass. 2. Glass has a deep and inconsistent pattern. It always seems to break while moving through the primary quench or during the first 60 seconds while it is in the secondary quench cycle. How can you improve the issue?

This latest #AskGlaston episode will answer two of your questions. 1. How to eliminate the rainbow effect and white smoke spots? 2. How to obtain consistent results from your tempering line?

This latest #AskGlaston episode will answer three of your questions. 1. How to reduce breakage in the quenching section? 2. What is the lifetime of a tempering line? 3. How to eliminate hot spots from tempered glass?

#AskGlaston Episode 3: How to temper Low-E glass with older tempering technology?

This is our second episode of #AskGlaston. Today, we’ll cover an interesting topic that glass users and processors question from time to time. Which has the best quality: tempered or heat-strengthened?

The glass business can be capital intensive, and experimenting can end up being surprisingly costly. The raw material alone is expensive, and each processing step adds value to the glass. A mistake or a problem later on in the processing can be quite costly. It doesn’t have to be that way!