In this second part of our blog on energy consumption in the glass tempering process, let me go deeper into details to explain some of the principles behind heating and cooling.

Knowing the derivation of different metrics will help you better understand the tempering process, as well as the costs linked to its energy requirements. Once learned, it’s handy to know, so that no one will ever be able to trick you with numbers by providing irrelevant or over-optimistic performance data.

Heating energy

The required energy to heat glass can be calculated with the formula:

E = ΔT * c * m, where

E = Energy required to heat the glass

ΔT = Temperature change

c = Specific heat capacity of the glass

m = Mass of the glass

Let’s take a 1 m2 sheet of 4 mm thick glass as an example. In this case, the values would be:

ΔT = 610 °C (from 20 °C to 630 °C)

c = 1.1 kJ / kg * °C

m = 1 m² * 2500 kg/m³ * 0,004 m = 10 kg

*Note that the specific heat capacity of glass changes as a function of temperature! The value at room temperature is about 0.78 kJ / kG * °C, whereas the mean specific heat capacity between +20 °C and +630 °C is about 1.1 kJ / kG * °C.

By placing these values into the formula above, we get:

E = 610 °C x 1.1 kJ / kg * °C * 10 kg = 6710 kJ = 1.9 kWh = 0.475 kWh/m²*mm

According to the calculated results, we see that it is impossible to heat a 4 mm glass sheet from +20 °C to +630 °C using less energy than 1.9 kWh. In more universal terms, this means that the heating requires at least 0.475 kWh/m²*mm. By multiplying this by the glass thickness, we get the minimum energy required to heat this piece of glass.

Keep in mind this is not all. To calculate the total energy consumption, you also need to add energy loss, convection blowers and the glass quenching process on top of the calculations above.

Quenching energy

The second phase of tempering is quenching. This is also the part where glass processors can most affect the total energy consumption per processed square meter. Why? Modern furnaces generally function so that the amount of glass to be tempered does not greatly affect a machine’s energy efficiency. This means it doesn’t matter whether you are going to use 5% or 90% of your maximum loading area. The energy consumption per square meter will be roughly the same in both cases.

In the quenching process, loading efficiency plays a much larger role. Chillers normally utilize the same blowing area in all cases. If you are using only 5% of your loading area, most of the energy created by the quench blowers is wasted.

The quenching energy required depends primarily on the utilized loading area – and then on the blower technology. As a good rule of thumb, with about 90% loading efficiency and modern blower technology, the required energy would be about 0.45 kWh/m² for 4 mm clear glass and 0.25 kWh/m² for 6 mm clear glass.

The table below illustrates the effect that loading efficiency has on the total energy consumption per square meter with 4 mm glass. The example is calculated with a 2.4 x 4.8 meter maximum loading area.

| Loading efficiency | 9% | 61% | 87% |

| Utilized loading area | 1 m2 | 7 m2 | 10 m2 |

| Heating energy | 1.9 kWh | 13.3 kWh | 19.0 kWh |

| Energy loss | 0.6 kWh | 0.6 kWh | 0.6 kWh |

| Quenching energy | 5.8 kWh | 5.8 kWh | 5.8 kWh |

| Energy consumption per square meter* | 8.3 kWh | 2.8 kWh | 2.5 kWh |

*The example above does not take into account energy required by convection because different technologies use different amounts of energy, which is why the figures in reality would be slightly higher. The purpose of this example is to illustrate the effect of loading efficiency and what the minimum rates might be that you could actually see in production.

As you can see, the effect of loading efficiency on energy consumption per square meter is huge.

From the example above, we see that the biggest energy savings are coming from the chiller side. Larger loadings lead to drastically reduced energy consumption per square meter processed.

However, furnace technology is key to being able to run large loads. When selecting a tempering furnace, make sure that it allows you to utilize its loading area as efficiently as possible without compromising on glass quality.

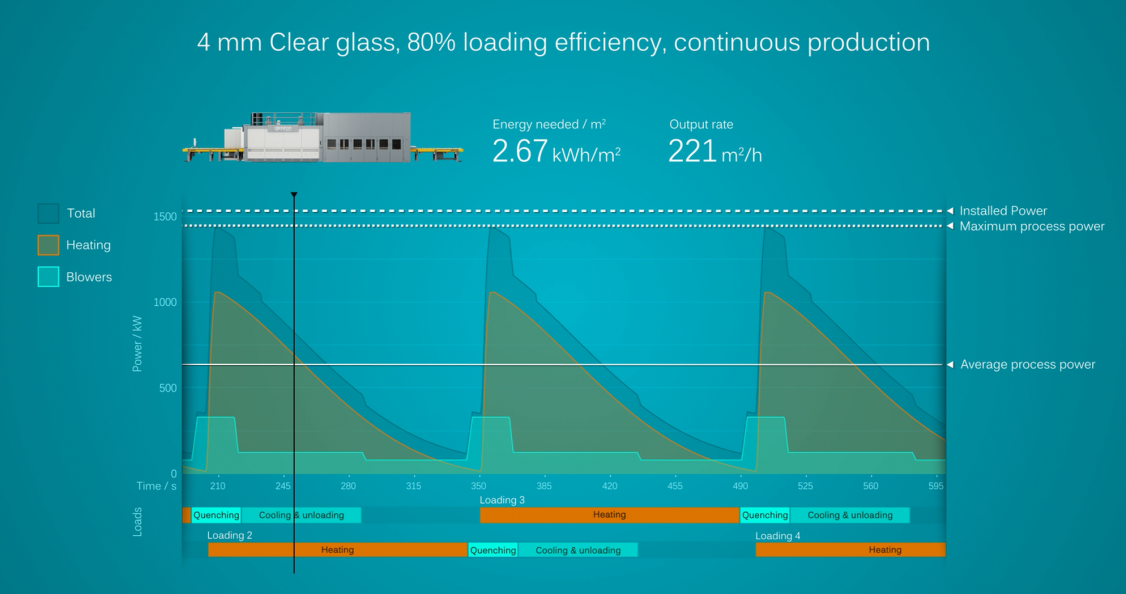

The impact of a machine’s connected power also comes into play here. If your furnace does not have enough power, it cannot handle running large loads continuously – even if it is able to process single loads. Your furnace must be able to recover from the previous load as soon as possible. If your furnace is not hot enough when the next load enters, you will face problems. When you can run your production without unnecessary loading delays, you can achieve higher capacity and also lower energy consumption per square meter because some energy is always lost when the furnace is on – whether or not there is glass inside.

To close, I hope this review of the energy consumption in each glass tempering phase helps you better understand the terms used by suppliers in the industry. I hope it serves you as a good practical check when selecting your next tempering line. And, most of all, I want you to be well-informed so that you can knowledgeably assess all the numbers, which may not be presented in your best interest.

For a good summary, you can check our Glass tempering energy consumption animation published some time ago.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.