Safety is the most important characteristic of tempered glass. When broken, tempered glass breaks into small pieces that do not cause severe injuries as larger glass pieces would. Additionally, increased tempered glass strength also adds to the safety factor.

While accidents caused by improperly tempered glass are rare, even a single accident is too much.

1. Break test

“Keep performing those break tests – what if it was your child that ran through an improperly tempered glass and got injured or worse?”

The break test is familiar to every glass processor with a tempering line. It’s a standardized destructive test that is performed periodically, every hour and with every product change, on a test glass piece (360 x 1,100 mm). The sample piece is broken. Then, the number of cullets is counted or weighed, depending on the used standard, to confirm that the glass was properly tempered.

To work as intended, the break test requires that tempering line operators always remember to follow the rules and document the results. While nobody intentionally skips the test, we’re all humans, and mistakes happen.

The quote at the beginning of this section is from a glass processor who said he uses this to remind operators to do the break test. It’s an excellent way to emphasize the importance of safety procedures.

But what if you dotted all the i’s and crossed all the t’s in the process, and somebody still got hurt? Unfortunately, this is still a possibility, as the break test has some other issues, as well:

While the break test already significantly reduces the likelihood of accidents, even a single accident is too much. So, what can we do to ensure that we are taking steps toward zero accidents?

2. Surface stress and middle-pane tension measurements

A non-destructive way of making sure that glass is properly tempered is to measure surface stress and middle-pane tension. Surface stress measurement is commonly referred to in the glass industry.

However, middle-pane tension is actually the more important measurement in ensuring proper fragmentation. It is possible to measure both variables with devices such as SCALP, a portable scattered light polariscope.

The main issue with measuring surface stress and middle-pane tension has been that it has to be done manually for each glass piece – and only after tempering. So, while it’s a good tool for process development, it’s not feasible to measure each and every piece of glass.

3. Online Stress Calculation

A third option introduced recently is Online Stress Calculation (OSC). This is a method that has been developed to tackle the inherent issues of option 1) the break test and option 2) surface stress and middle-pane tension measurements, namely:

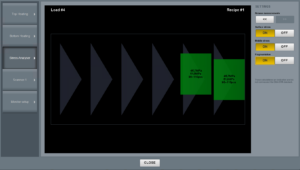

Online Stress Calculation provides measurements of glass surface stress and middle-pane tension as well as an estimated fragmentation amount for all processed glass. OSC is directly integrated into the tempering line operating system, and all results are based on actual measurements of critical process variables during the tempering process.

A system such as OSC will significantly decrease the risk of accidents. The system will automatically provide alerts if calculated values are lower than they should be. Moreover, glass processors will be able to provide proof to end customers of the tempering level of each and every piece of processed glass.

Click here if you’d like to learn more about how OSC works.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.