With newer and more exciting trends shaping the automotive industry every year, the automotive business is always in the fast lane. In this blog post, we look at trends in the sunroof and windshield business today and how glass processors can prepare for them.

It might seem that the whole world came to a stop recently and nothing much has happened. But the automotive industry’s engines never stopped running, and light vehicles and buses are racing back. In addition, today’s unique challenges have generated several new trends in automotive glazing.

In short, we can clearly see that glass is getting bigger, thinner and more complex, creating extra challenges for glass processors.

First of all, the technology integrated into the glass unit continues to increase. In windshields, for example, you now have cameras, rain detectors and other sensors –all of which need to be hidden. This results in the ever-increasing size of screen-printed areas. In sunroofs, the screen-printed area can constitute up to 50%.

Not only is the glass used in the automotive business getting bigger, at the same time it’s getting thinner. The trend toward thinner glass is being driven by the global requirement to cut CO2 emissions by reducing glass weight. Thinner glass increases the range of battery-powered cars. The combination of thinner and larger glass is a daunting challenge for any glass processor.

Last but not least is a more frequent need to use coated glass. Typically, this refers to the sunroof business, but we are seeing it in the windshield segment as well. Although this is not the most widespread trend, we believe glass processors need to be prepared for this one to gain momentum in the future.

State-of-the-art technology can help automotive glass processors keep up with the trends.

Is your glass processing equipment capable of meeting the highest quality standards? Is it able to process the most complex glass required by the market today?

As automotive glass gets thinner, it creates special bottlenecks when preprocessing the glass. To avoid those, the process requires greater cell setting care.

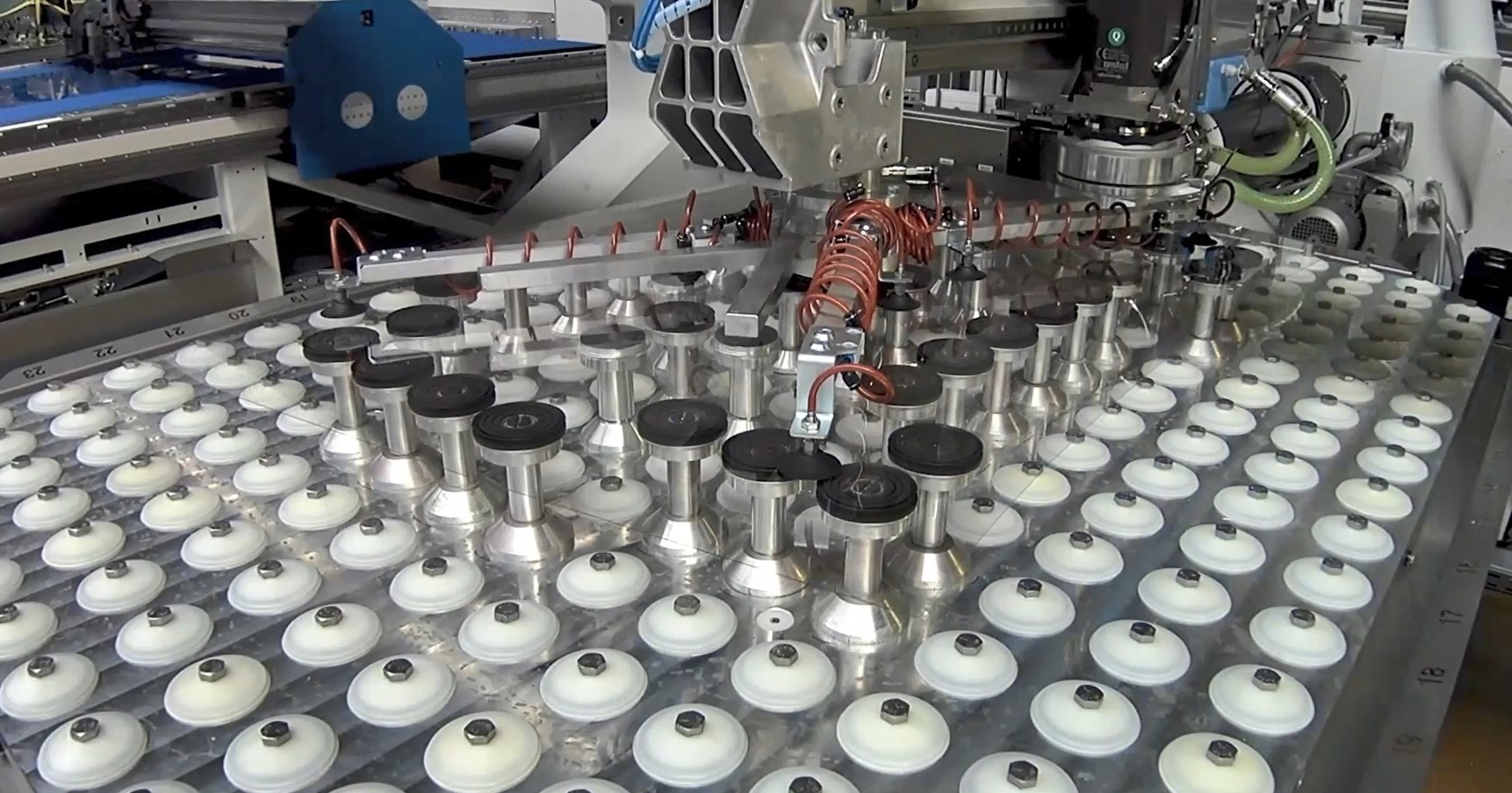

This includes additional stabilization during the handling, cutting and break-out, as well as grinding processes, applying lower cutting and breaking pressures and using smaller cutting wheels. A slower handling device speed, especially during acceleration and lifting, is another factor to consider during preprocessing. And lastly, stable support and smooth surfaces are needed on all glass touching points to avoid breakage.

That’s why the equipment required for thin automotive glass preprocessing today should include fine and adjustable cutting and breaking tools for precise control of low cutting pressures. Another good device to consider is a special jet ring with an optimized coolant supply for low deflection of thin glass and exceptional edging.

With heat treatment, if the furnace control matrix allows focusing heat on even the smallest zones, it will be possible to run glass with wide screen-printed areas or any other elements that make glass processing more challenging.

To meet the increasing automotive glass size requirement, make sure your furnace can run glass as large as 2,600 x 1,700 mm.

And most importantly, take note of convection.

With conventional heating technology, such as radiation, there is always a temperature difference between clear and screen-printed or digitally printed areas. This is because printing absorbs more radiation than clear glass.

Convection, however, heats the whole unit evenly. And this also applies to coated glass.

Additionally, convection enables faster glass heating. With a faster preheating cycle, we have a longer window for glass shaping, leading to better shaping capability and overall process repeatability.

You can learn more about the benefits of convection technology from this article here.

In the automotive business, trends never stop shifting gears. The better you prepare for the trends of today, the easier it is for you to get ahead of the competition and meet the next turn in the road.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.