Strong, resilient, with perfect thermal and sound insulation properties, insulating glass has been used around the world in applications ranging from family homes to high-scale construction. Its unique design structure makes it ideal glazing material and a product with strong growth prospects. But what makes insulating glass the most preferred choice in so many applications? In this blog, we discuss the different types of insulating glass units and their special characteristics.

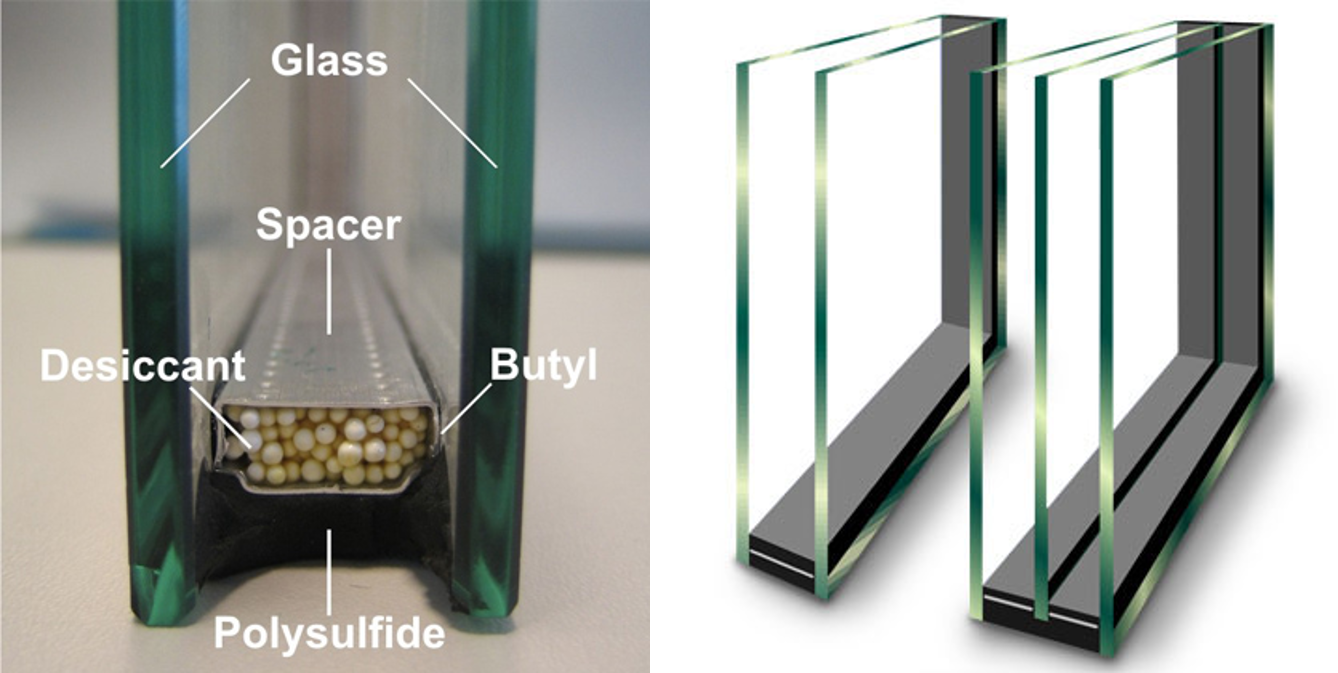

An insulating glass unit is a contemporary glass composed of multiple panes sealed together with air space in between, which gives the glass its insulating properties by separating the outside pane from the inside pane. Thanks to this unique arrangement, insulating glass is the most effective way to reduce air-to-air heat transfer through glazing.

Insulating glass dates back to the 1960s when the concept of saving energy became popular. Today, when used together with Low-E or reflective glass coatings, insulating glass is even more effective in conserving energy and complying with energy codes.

Depending on the application, insulation requirement or end user’s need, insulating glass is available in numerous different types. Design versatility is based on factors, such as the number of glass panes used in the unit production, cavity-filling material, coatings, sealing material and others.

Because ordinary glass fails to sustain expected wind forces and severe weather conditions, it is an unsafe material choice for outdoor applications. In turn, the increased strength of insulating glass units makes them the most preferred glass type for residential, commercial and industrial structural glazing. Multiple layers of glass boost the strength of the design element, making it more durable, resilient and secure.

What also makes insulating glass a perfect choice for windows and doors is its adaptability to different seasons. Insulating glass was primarily designed to protect glazed areas from excessive heat loss or gain. During the summer, this glass blocks the sun’s heat from entering into the interior. In the winter, it prevents indoor heat from escaping outside.

Basically, insulating glass is truly an eco-friendly glazing option. Thermal insulation allows it to take the load off heating and cooling equipment. It also makes it much easier to achieve a desired indoor temperature without excessive use of power and energy. And this is a big deal when reducing heating and air conditioning costs, as well as the carbon footprint.

Compared to ordinary single glass, insulating glass also has the added advantage of minimized condensation issues.

But from the design perspective, insulating glass offers a wide range of solutions for both large and small structural glazing projects. It can be used, for example, to construct visually impressive all-glass façades or compelling architectural façades by using profiles that are only visible from the internal side.

With increasing road, rail and air traffic, noise insulation has become a very important glass property. Today, noise insulation is an undisputed requirement in building construction to help eliminate stress and noise-related issues.

Insulating glass, in turn, is a perfect barrier against undesired noise. Its effective sound control feature makes it ideal for residential applications where the need for seclusion is important.

Without sacrificing daylight, the desired acoustic performance of sound control glass is achieved by combining various thicknesses of glass with a PVB interlayer within the double-glazed unit. When even greater sound control is required, adding a wider space between the glass panes can help.

Widely used in bank counters, escort vehicles and other security-related applications, bulletproof glass is another product type where insulating glass is preferred.

Bulletproof glass is produced by combining two or more sheets of glass with PVB interlayers to prevent a bullet from passing through. Its lamination property enables the glass to provide impact protection and extra security. If damaged, the glass breaks into numerous small cullets, reducing the risk of serious injury.

Higher levels of security are obtained by increasing the number of layers and glass thicknesses.

The insulating glass used in bulletproof applications is typically up to five times stronger than annealed glass of the same thickness and eliminates the risk of thermal fracture.

Fire-resistant glass (FRG) is designed for interior and exterior use when thermal protection is required in case of fire. This type of safety glass is mainly produced using clear, multi-laminated, fully insulating glass.

Different fire-resistant glass units offer varying levels of protection. These are measured in terms of glass integrity and insulation levels. The integrity characteristics determine the time the glass remains intact in a fire. Insulation defines how much the glass limits the temperature rise on the non-fire side.

Depending on the product quality, fire-resistant glass should also ensure protection from radiation and passive protection from the effects of fire for up to 180 minutes.

As you can see, there are different types of insulating glass, each with its own composition, performance characteristics and purpose. Still, one thing remains constant – all insulating glass has unrivaled heat insulation, sound insulation and impact resistance.

If you are looking for more information on insulating glass and its production technologies, your next click should be the IG Manufacturing Line Buyer’s Guide.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.