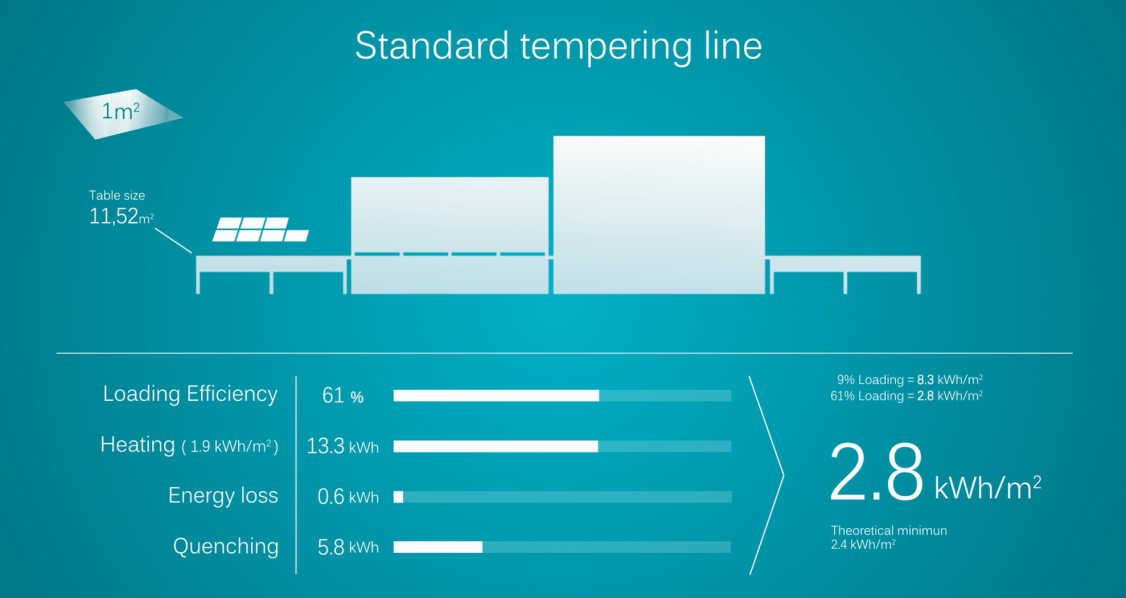

Energy consumption is always a key topic when looking to invest in a new tempering line. The reason is simple: the tempering process requires a lot of energy. So, energy costs are a major part of the tempering line’s operating costs. That’s why tempering equipment manufacturers keep making their lines more energy efficient – and also why you sometimes see unrealistic claims regarding energy consumption.

The automotive industry offers a good analogy. The trend has been towards cars that use less fuel and produce fewer emissions. Tightening regulations have been one of the main drivers of this trend. But fuel prices too play a big role in car ownership, so buyers are also becoming more demanding. The result is more environmentally friendly cars on our streets. But another outcome has been the cheating we’ve seen to achieve higher performance rates with lower investments.

Two years ago, we published a blog post called “The Volkswagens of the glass tempering business” to address the same issues in the tempering line manufacturing business. If you haven’t had a chance, check out that article for a real-life example.

Two years have passed and the issue is still here. We constantly facing situations where some people claims glass can be tempered using less energy than is required for glass heating according to the laws of physics.

That’s why I feel it is necessary to take this discussion into specifics. For a quick summary, check out our Glass tempering energy consumption animation.

Glass tempering consists of two phases: heating and quenching. First, glass must be heated to a temperature well above the transition point of +567 °C but below the softening point of +710 °C.

Usually, glass needs to be heated to a temperature of at least +630 °C to achieve a good tempering result. After heating, the glass must be cooled quickly and uniformly at a controlled rate well below the strain point of +510 °C. Only after this phase can the glass be cooled further to reach its handling temperature.

If you are interested in reading more about the physics behind glass tempering, take a look through the Glass Tempering Handbook.

It is important to understand the terms that are used when discussing energy consumption. These terms may vary a bit in different companies, so most importantly, always make sure the figures you get include everything from heating to cooling. This includes all metrics and variables in the heaters, convection as well as energy losses from the furnace and the blowers. Also make sure the numbers reflect real, continuous production.

Below are the most common terms you will need to gain a better understanding of this topic.

For 10 mm glass, this would mean that a minimum 4.75 kWh/m² is required for heating alone. On top of that, you need to add quenching. So, when you see values that are lower than what is minimally required for heating, you know right away something is wrong.

The case described in the article “Volkswagens of the glass tempering business” is a good example of the situation when the manufacturer claims that its equipment can run the whole tempering cycle with only 0.20 kWh/m²*mm.

This is a radical example, but unfortunately, situations like this are not as uncommon as you may think. If a supplier is intentionally giving you false information to make its equipment look better, who knows what other data has been tweaked to get your business?

At this point, it’s fair to ask why you should believe the figures above.

In the next blog post, I will explain some theory behind the numbers, so you can understand the physics behind those numbers. I’ll also discuss heating and cooling in more detail. No disreputable supplier will ever be able to pull the wool over your eyes after that.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.