This is a real life story that represents a very common situation at many glass processing factories. It’s a story of making things right with what you have and really digging in to find the root cause of your business or production challenge. If you are a glass tempering line operator, you can find a couple of practical hints. If you are a business manager, you can reflect on whether this is the situation in your factory.

A couple of weeks back, I visited one of our existing glass tempering line customers. They have an approximately 10-year-old flat tempering furnace from Glaston, formerly Tamglass. Since their business has been good thanks to the furnace, the company is now planning to make its next tempering line investment. We started talking about the current market needs, and how those affect the requirements of today’s tempering line investment.

We talked about the new temperable soft coatings with emissivity of 0.01, the trend for larger glass sizes, new thin glass applications, today’s quality requirements for tempered glass, energy consumption, the growing competition, the importance of cost control – and many other things that need to be considered when making a tempering line investment.

At some point, our customer mentioned as a side note that he has challenges with an approximate 2 x 3 m, 6 mm black tinted glass. I told him that he should not have any challenges, since the machine is more than capable of running that glass size. So we went to see the machine together.

As we came to the unloading table, it was easy to spot that the glass had terrible roller wave and was bent. We went on to the operating panel and looked at the recipe:

I asked the operator if there was a reason why he was using such a long heating time and high furnace temperature. The answer was: “If I decrease the heating time or the temperature, the glass starts to break.”

Roller wave, image source: © Glaston

Searching for the root cause

We walked around the factory before making any adjustments and spotted a clear fault on the pre-processing side. As we passed one grinding machine, almost all the glass pieces of a certain size had a relatively large crack in one specific part of the glass. Then things started to make sense. The operator needed to compensate for the poor edge grinding quality by overheating the glass excessively!

After spotting this we started to tune the recipe. I called to one of our process experts to confirm some parameter levels. The 730 °C for that specific glass tempering machine (Glaston-Tamglass HTF Super) the furnace temperature is too high. The first action was to decrease the overall furnace temperature. After this we slowly started to decrease the heating time. At the same time we needed to decrease the air balance (to make the pressure adjustment in the quench section more even).

Earlier, when the glass was so much overheated it was actually bent already when existing the furnace. The high air balance setting tried to overcome this but actually it tried again to correct a mistake that was already made. If you need to run with 37% level air balance there has been already a mistake in the heating section. This advice applies on both clear and tinted glass.

Getting the process right. Picture source: ©Glaston

This is not the first time I see a tempering line operator (or the line itself) being blamed for a mistake that happened much earlier in the process. This is an advice I can’t stress enough: always do the root cause analysis on the quality problems you have! There are excellent tools for this. One that I really like is the fishbone-diagram, aka cause-and-effect-diagram. I’m sure this is familiar to those who have been involved in LEAN manufacturing philosophy.

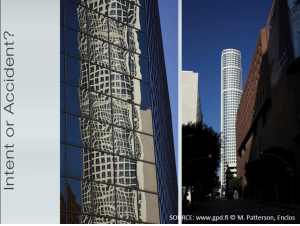

We know this situation is very common in many glass processing factories. And sadly many of the poor quality glasses end up being installed in buildings. The poor quality always leads to decreased customer satisfaction and decreasing amount of repeat orders. This is why I can’t stress enough the importance of training at all levels of the organization. You can get your internal guys to do the training once in a while or ask for the assistance from the tempering line manufacturer like Glaston.

Picture source: www.gpd.fi ©M. Patterson, Enclos

Back to this customer’s new line investment: we agreed together to first set the process right for the existing line by arranging a proper training program for all of his operators. Only after this can we better plan the next investment and the best way to split the production between these two lines.

We already know one big difference between the existing line and the new one – size. Did you know our most-sold glass tempering line size was 2.4 m x 4.8 m just 8 years ago, whereas today it’s 2.8 m x 6.0 m?

PS. The images shown in the article are not related to this particular case.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.