Windshields for both long-haul and city buses have evolved over the years. Today, they require much more sophistication to keep up with the latest environmental and production regulations. Passengers and drivers, too, require more in terms of comfort and safety. By selecting modern technology, glass processors can effectively serve both markets while staying competitive despite the changing market requirements.

Throughout the world, the major trends of energy efficiency, CO2 emissions reduction and lowering manufacturing costs are affecting the design of modern buses and further guiding the design of bus windshield glazing. Still, today’s bus market can be roughly divided into two different segments that vary considerably from each other in terms of usage, market volume and technology:

Long-haul buses are primarily operated by private operators for chartered or scheduled long-distance service. The fleets are usually small and therefore, the equipment is purchased in low numbers. They are used for longer distances on highways at high speeds. This places tight requirements on the aerodynamics of these buses to lower fuel consumption and noise. Further, attention is focused on passenger comfort and aesthetics, while luggage room adds to the bus height.

The public transport segment is totally different. These buses are typically operated by public service companies that cover inner city transport. The fleets are large, and consequently bigger numbers of equipment are needed. Cost alone is a primary issue. Fuel consumption for city buses is important too, but the shorter routes and lower speeds do not set as tight requirements on the aerodynamics or shape of the windshields. Still, maneuvering in busy traffic requires good visibility. And to reduce emissions, lightweight solutions are required, leading to the use of thinner glasses in windshields and sidelites. Due to the importance of cost, designers look for simple shapes, cost-effective constructions and an effective supply chain that also considers replacement service and costs.

Since the entire bus windshield market is relatively limited, glass processors must therefore aim to serve both market segments to be competitive. To match the needs of both segments, a processor needs equipment with the flexibility to process very short series or even single pieces.

This article gives a short overview of how the bending equipment has evolved and what kinds of solutions are available for windshield processing today.

A windshield gets its final shape during the bending process. If the bending process fails, the whole process fails as well. The optics, installation shape and functionality mainly all depend on the quality of the bending process.

Traditionally, bus windshields have been manufactured with slow, low-yield, single-chamber furnaces. A typical furnace has one chamber for preheating, bending and cooling along with a movable bottom with a mold on which the glass lays. Single-chamber furnaces are still used today, but mostly for very limited production or for the bending of only the most demanding shapes of larger monoblocks with wrap-around corners or spherical shapes with an accentuated double curvature. The main advantage of this kind of furnace is the possibility to interfere with the bending process manually from outside at any stage of the bending, if needed.

The first serial furnaces for large bus windshield processing were introduced in the early 2000s. The early bus windshield furnaces were relatively simple in terms of construction, heating, mold technology and controllability. They were primarily used to bend easy shapes and relatively small sizes.

The serial furnace offers a range of advantages over a single-chamber furnace. First, the process is more productive and energy efficient. This is because the most expensive part is the bending section, and it is used only at the end of the heating process to bend the final shape. Second, the repeatability and yield are better, as the furnace consistently repeats the heating process under the same conditions. Third, energy consumption is lower, since part of the heat remains in the process through the cooling. And finally, a serial furnace takes less factory space. And since it is a modular construction, it can also be extended later.

To use the serial process for more demanding shapes, special attention must be paid to the heating, mold operation and controls. The bending capability of a serial furnace can be enhanced by integrating glass supports, triggering devices, mold-related techniques and by improving the heating control.

The more demanding the shape, the more focused the heat in the bending sections needs to be. Overall heating, from the top, bottom and even from the sides, is recommendable when it comes to processing demanding glass shapes. The heaters in the ceiling can be divided into several parts. The most advanced furnaces have up to five or seven upper heating parts.

The bottom heating can be divided into several control zones to improve the heat focus on the glass surface. Power regulation is a standard feature in modern furnaces, thanks to the competitive pricing of solid-state relays.

The focus can be further enhanced by using reflective plates or parabolic grooves above the heaters to reflect the heat radiation down onto the glass surface. This also helps reduce scatter radiation and optimize the heating power. A lower heating power also means that a smaller transformer can be used, thus reducing the overall investment cost.

A typical bus windshield has tight wings on the sides. Therefore, some models may need fairly aggressive heating on the lateral folds. The heating can be intensified in two ways: using extra mold heaters or by vertically adjusting the top heaters.

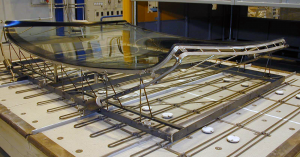

Heat control is only one part of the process. Another important part is the mold and mold-related technologies. Large, thin glass needs to be supported during the preheating stage. It is then released gradually in the bending section where the shaping starts. The most common tool today for this is a mold-based support, which is released and lowered using an automatic central support for the bending.

Tight wings are usually bent using extra heaters for the folds and hinged molds with counterweights. The repeatability of wings shaping can be increased by using an automatic wing control device, which supports the weights and is lowered gradually during the bending process. A modern furnace has a fully automatic wing control device, which can be controlled from outside the process according to the specific recipe.

Black ink on a glass surface absorbs the heat radiation more efficiently than clear glass. This complicates the heating process and thus must be compensated for by means of absorption plates or heat covers on the molds.

Optical quality and accurate shapes are becoming increasingly important criteria for bus manufacturers. The traditional rubber ring fixture has allowed larger tolerances than the glued constructions used today. With the glued construction glass has become an integral part of the body, requiring more accurate production tolerances for the glass.

In an automatic furnace, each windshield is bent according to a preprogrammed recipe, which defines the heating power, heating pattern, triggering times, cooling times, and other parameters for each process step. The process steps are controlled either based on time, air temperature or glass temperature.

Bus windshields are mainly bent in mixed or short production runs. The best results can be achieved by using a combination of glass temperature and time. Since the main process and shaping follow the glass temperature as measured by optical infrared pyrometers, the movements and control of triggering devices can be based on time settings. For preheating, the air temperature-based control is precise enough.

An interesting new control innovation in the field of control is based on measuring the glass position, or sagging, during the bending. The cooling can be triggered at any precise point during curving, giving the process even better repeatability.

Symmetrical heating is critical, especially when bending two glass halves in the same wagon. Symmetrical heating can be guaranteed by using a temperature balancing system. The system consists of two symmetrically placed pyrometers and a control algorithm, which compares the glass temperature of each half and compensates the differences once measured.

The average size of glass as well as the total amount of glass used in a bus is continuously increasing. Instead of a plain single lite windscreen, the modern double decker may have up to three lites in the front of the bus: the windshield itself, the destination glass and the upper windshield.

Integrated new technologies, such as heating systems, coating, antennas and display systems, open new business opportunities for glass processors. Instead of selling a plain piece of laminated glass, the future glass processor will be selling a transparent component with value-added functionality.

These trends set greater requirements on the bus windshield processing equipment and production control. To stay competitive, glass processors must continue to develop their equipment and adapt their processes to the new and ever evolving requirements of the market.

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.