I want you to think about your daily journey to work. Take a minute, visualize it – and then answer me this: How many glass surfaces did you see? Too many to remember?

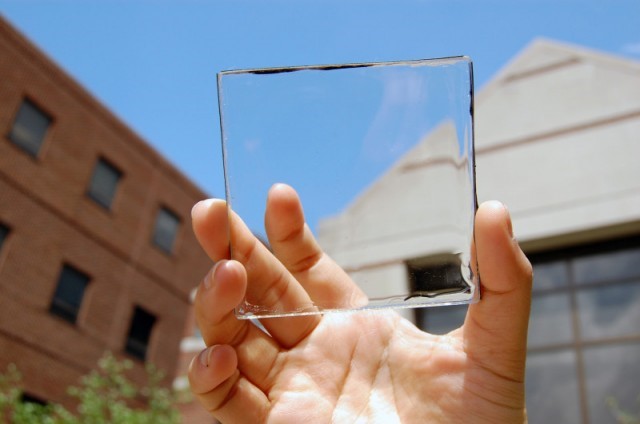

Well, there’s a point to all this. Back in August 2014, researchers at Michigan State University created a fully transparent solar concentrator, which could turn any sheet of glass into a solar cell. This means that every glass surface that you see on your way to work, or you’re planning or already producing at work, could be a small solar-powered energy generator. That’s something to think about!

Essentially, transparency is achieved by shrinking the components. And shrinking means that the cells are fundamentally altered so that the way they absorb light is changed.

After the cell is altered, it selectively only harvests the parts of the solar spectrum we can’t see with our eyes. So it captures the ultraviolet and the infrared parts of the solar spectrum. The rest of the spectrum is free to pass through. And this is what makes the panels transparent.

In more detail, the team that created all this used a slightly different technique for gathering sunlight.

They did not choose to create a transparent photovoltaic cell. Instead, they used a transparent luminescent solar concentrator (TLSC). According to the team’s research paper, the TLSC consists of organic salts that absorb specific non-visible wavelengths of ultraviolet and infrared light, which they then luminesce as another wavelength of infrared light (also non-visible). This emitted infrared light is guided to the edge of plastic, where thin strips of conventional photovoltaic solar cell convert it into electricity. [Research paper: DOI: 10.1002/adom.201400103 – “Near-Infrared Harvesting Transparent Luminescent Solar Concentrators”]

The interesting part of this innovation is that not only could it be implemented in new buildings while the building appearance would stay exactly same, but it can also be used as a retrofit for current building structures by laminating the transparent solar cell window from the inside onto an existing window.

And, of course, this is not restricted only to buildings. This technology could be applied to smartphones and automotive applications as well. With the rise of electric cars, imagine a situation where you’d leave your car in the sunlight and it would charge itself with a fully transparent windshield, panoramic roof glass or all its other glass surfaces.

It is worthy to note that there are already successful prototypes of this technology being made. Forecasts predict that we will start to have actual products available in a couple of years. So this is not any kind of Sci-Fi that might be possible in the next 20 years. This is happening now.

Taking into account that this is the actual future of glass, we need to look into how glass processors can benefit from this trend. Naturally, the good news is that the demand for glass is going to keep on increasing because of innovations like this.

This technology shall support the growth of the thin glass market since, for example, the retrofit application will require a very thin glass to be laminated to existing glass panels.

The quality aspect will also remain important in the same way. The glass needs to be heat treated for many different applications. And the innovation in question requires very flat and good quality glass. Therefore, this further supports the growth of super flat, no-roller-wave glass.

The tempering line manufacturers have responded to the growth of smart glazing by developing new technologies to reach even better quality levels than required in mainstream applications. For example, two years ago, Glaston introduced its GlastonAir flat tempering machine, which is capable of processing very thin heat-treated glass of less than 2 mm with safety glass properties.

So far, one of the biggest barriers to the large-scale adoption of solar power is the intrusive and ugly nature of solar panels, along with the enormous space requirement for solar farms. Obviously, if we could produce large amounts of solar power from glass panels that look like normal sheets of glass, then that would be just incredible. Or what do you say?

Today, many glass application development projects concentrate on bringing intelligence into the glass pane. This doesn’t only apply to transparent solar cells but to all kinds of smart-glazing applications, like electrochromic devices. Many of the different smart-glazing applications are perhaps not yet bringing sufficient production volumes to glass processors – but in the very near future, they will. Trust me.

Read more about the glass and energy in the GPD 2015 summary presentation:

Sign up for Glastory newsletter

We answer your questions about glass processing. Let us know your challenges and we promise to do our best to help you.

Comments are closed.