Glass breakage in the tempering furnace is something that we all want to avoid. In this #AskGlaston episode, we are looking at the factors that can lead to the breakage of thick glass in a radiation furnace. The other question refers to the difference of heat-strengthened and tempered glass.

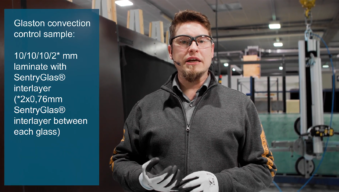

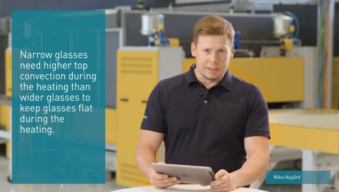

This latest #AskGlaston episode will cover two questions devoted to the issues of improving the production of special coated and patterned glass. 1. How can you improve the continuous production of 8 mm Low-E triple-layer silver-coated glass. 2. Glass has a deep and inconsistent pattern. It always seems to break while moving through the primary quench or during the first 60 seconds while it is in the secondary quench cycle. How can you improve the issue?

This latest #AskGlaston episode will answer two of your questions. 1. How to eliminate the rainbow effect and white smoke spots? 2. How to obtain consistent results from your tempering line?

Once again, over 500 glass professionals gathered in Tampere, Finland, to celebrate glass. After many workshops and excellent presentations, I am excited to see the ambition level of glass industry professionals on the rise once again. If nothing else, the Glass Performance Days reminds us that glass is a material that can truly do it all.

And as a brief reminder, I compiled five design trends that caught my attention.

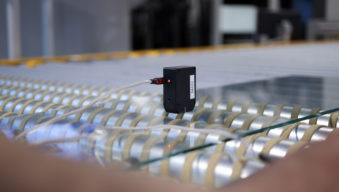

This latest #AskGlaston episode will answer three of your questions. 1. How to reduce breakage in the quenching section? 2. What is the lifetime of a tempering line? 3. How to eliminate hot spots from tempered glass?

From time to time, I get a question from the glass structural engineers about specification advice on glass quality for high-profile facades. How they can make sure they will get the best possible or most suitable glass quality for their project? Many times, the question is: what is the best I can realistically get from the market?

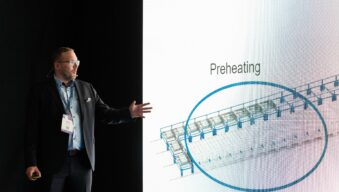

Energy efficiency is becoming a major concern in the windshield manufacturing industry. Whatever system or technical solution you’ve chosen for your windshield manufacturing facility, one of the keys to profitable operation and fast payback is to continuously improve the energy efficiency of your operating machinery.

#AskGlaston Episode 3: How to temper Low-E glass with older tempering technology?

Energy savings in glass tempering process goes directly to your bottom line. Here’s how you can minimize your tempering process energy consumption. (Part 2/2)

This is our second episode of #AskGlaston. Today, we’ll cover an interesting topic that glass users and processors question from time to time. Which has the best quality: tempered or heat-strengthened?

La neblina blanca en el vidrio templado es un defecto que debe corregirse de manera inmediata. Lea aquí qué es la neblina blanca y cómo se puede eliminar.

Exciting developments in the automotive industry have had a major impact on windshield design and functionality in recent years. This development is forcing windshield manufacturers to up their game. Not only do they need to adhere to increasingly stringent end-product safety and quality requirements, their windshield products must also answer designer demands. They must feature “smart” functionality, be fast to produce and environmentally friendly. This article introduces some of the current trends that are now shaping the automotive glass processing industry.

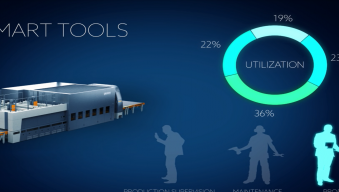

The glass business can be capital intensive, and experimenting can end up being surprisingly costly. The raw material alone is expensive, and each processing step adds value to the glass. A mistake or a problem later on in the processing can be quite costly. It doesn’t have to be that way!

Poner en marcha una línea de templado y que funcione sin problemas requiere la planificación y la colaboración entre el comprador y el proveedor. A continuación, describimos los 10 pasos para tener éxito en un proyecto de línea de templado.

Market requirements are moving toward more personalized solutions instead of huge volume ones. This trend sets new requirements also on your processing machinery.

If your glass processing equipment is not running, it’s costing you money. You must make sure you have a strategy to keeping your money-makers running.

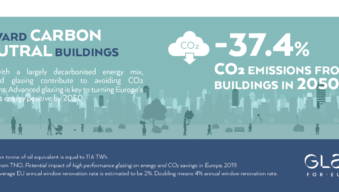

Glass and glazing solutions are an excellent way to increase the amount of daylight in any building or space. Read more to find out about the surprising impacts of daylight exposure.