Once again, over 500 glass professionals gathered in Tampere, Finland, to celebrate glass. After many workshops and excellent presentations, I am excited to see the ambition level of glass industry professionals on the rise once again. If nothing else, the Glass Performance Days reminds us that glass is a material that can truly do it all.

And as a brief reminder, I compiled five design trends that caught my attention.

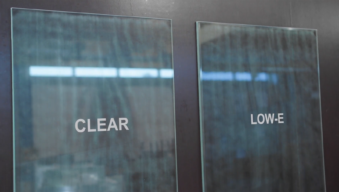

Energy efficiency is becoming a major concern in the windshield manufacturing industry. Whatever system or technical solution you’ve chosen for your windshield manufacturing facility, one of the keys to profitable operation and fast payback is to continuously improve the energy efficiency of your operating machinery.

Energy savings in glass tempering process goes directly to your bottom line. Here’s how you can minimize your tempering process energy consumption. (Part 2/2)

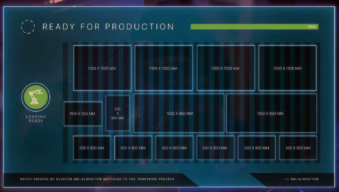

Getting a tempering line up and running smoothly requires planning and cooperation between the buyer and supplier. Here we outline the 10 steps of a successful tempering line project.

Energy savings in your tempering process goes directly to your bottom line. How can you minimize your tempering line energy consumption? (Part 1/2)

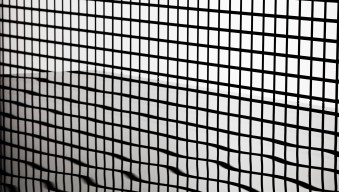

Optical issues are becoming more critical as a topic in high-end facade projects. Optical defects are caused due to two main reasons: roller wave and edge kink. In this article, I will discuss about roller wave and how to improve it.