From time to time, I get a question from the glass structural engineers about specification advice on glass quality for high-profile facades. How they can make sure they will get the best possible or most suitable glass quality for their project? Many times, the question is: what is the best I can realistically get from the market?

White haze in tempered glass is a defect that needs to be corrected immediately. Read here what white haze is and how it can be removed.

Markets demand increasingly more quality from glass suppliers. Sometimes, you can see weird strain patterns or rainbow-colored streaks in the glass, especially when viewed at a close angle and in polarized light. This is called glass iridescence. And here’s how to get rid of it.

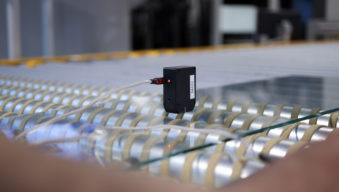

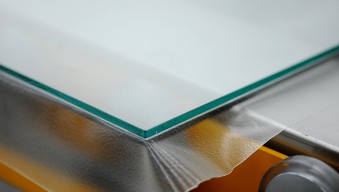

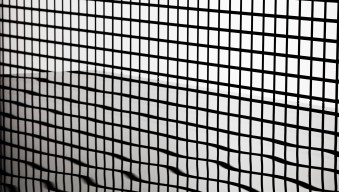

Optical issues are becoming more critical as a topic in high-end facade projects. Optical defects are caused due to two main reasons: roller wave and edge kink. In this article, I will discuss about roller wave and how to improve it.

Since we are talking about safety, it is crucial that tempered glass is actually tempered when it is delivered to customers. Here’s a list of ways you can make sure you don’t need to recall your glasses.