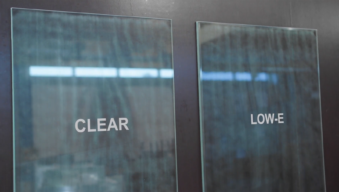

This latest #AskGlaston episode will cover two questions devoted to the issues of improving the production of special coated and patterned glass. 1. How can you improve the continuous production of 8 mm Low-E triple-layer silver-coated glass. 2. Glass has a deep and inconsistent pattern. It always seems to break while moving through the primary quench or during the first 60 seconds while it is in the secondary quench cycle. How can you improve the issue?

Energy efficiency is becoming a major concern in the windshield manufacturing industry. Whatever system or technical solution you’ve chosen for your windshield manufacturing facility, one of the keys to profitable operation and fast payback is to continuously improve the energy efficiency of your operating machinery.

#AskGlaston Episode 3: How to temper Low-E glass with older tempering technology?

Exciting developments in the automotive industry have had a major impact on windshield design and functionality in recent years. This development is forcing windshield manufacturers to up their game. Not only do they need to adhere to increasingly stringent end-product safety and quality requirements, their windshield products must also answer designer demands. They must feature “smart” functionality, be fast to produce and environmentally friendly. This article introduces some of the current trends that are now shaping the automotive glass processing industry.

The glass business can be capital intensive, and experimenting can end up being surprisingly costly. The raw material alone is expensive, and each processing step adds value to the glass. A mistake or a problem later on in the processing can be quite costly. It doesn’t have to be that way!

Getting a tempering line up and running smoothly requires planning and cooperation between the buyer and supplier. Here we outline the 10 steps of a successful tempering line project.

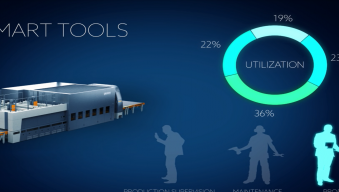

If your glass processing equipment is not running, it’s costing you money. You must make sure you have a strategy to keeping your money-makers running.

Energy savings in your tempering process goes directly to your bottom line. How can you minimize your tempering line energy consumption? (Part 1/2)

One of the most burning topics in the glass industry is whether anisotropy is a defect or not? The industry is puzzled because of a lack of standardization. What can we do?