Today, almost all new devices – from home appliances to production equipment – are connected. Rapid development in consumer electronics has been increasingly moving towards industrial use. In the glass industry, this development is still in its early stages. Nevertheless, it can already be clearly seen that the Internet of Things (IoT) applications can enable improved production efficiency and quality.

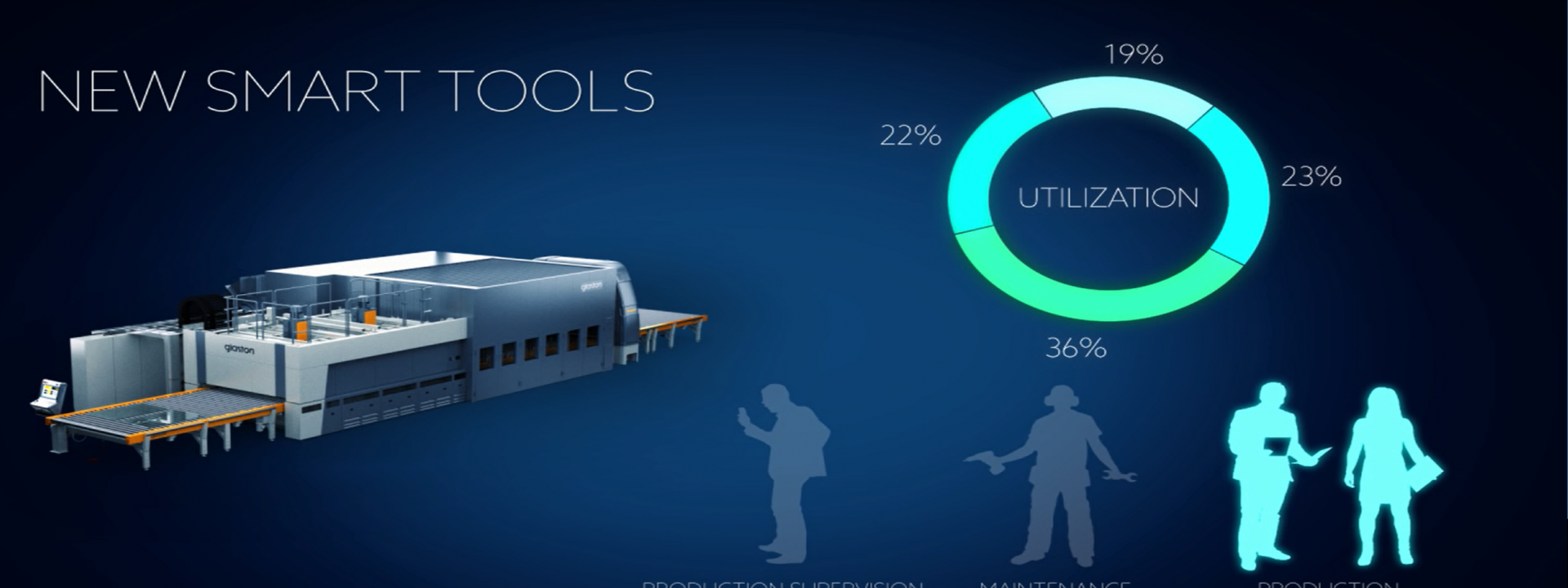

One smart platform that utilizes IoT in the glass industry is Glaston Insight. The system brings you intelligent tools to improve the productivity, uptime and profitability of glass processing machinery. When IoT is integrated, heat-treatment machinery can be monitored online, which allows immediate feedback.

For a more in-depth review of the benefits provided by IoT for a glass processing factory, you can refer to an earlier Glastory article: “What can online access to my machinery data (IoT) do for me?”

Knowing your production thoroughly is key to increasing efficiency. This includes throughput, energy consumption, lead times, variations between operators and shifts… and the list goes on.

In many cases, however, these factors are not clearly known or easy to calculate. Fortunately, with latest technology in place, your tempering line will be able to provide you with this information automatically! While reporting features continue to become more advanced, so does your production.

Equipping your factory with IoT solutions means that you will always have up-to-date information available online. With smart reports, it is easy to see which areas of your production need to be further developed. This may be increasing yield, optimizing capacity or avoiding overprocessing, to mention a few.

Even though we have merely scratched the surface of the possibilities that IoT and smart data analysis bring, the first glass processors who have embraced IoT solutions are now already enjoying the benefits. So, the question is what does the future hold for the glass industry with IoT being integral part of it, and how can we make tempering lines even more intelligent to enhance productivity?

When more and more machines become interconnected, the benefits of the networking will come into play. The Internet is a good example of the network effect – the more users there are, the more content, services and value are created for the individual users. The same logic applies also to glass processing when the machines are networked. The key is to be able to make the most of the vast amount of data – also known as big data – turning all the numbers into valuable information.

Big data can be defined as large and complex data sets that cannot be handled with traditional processing applications. This is why utilizing big data hasn’t been very effective in the past.

Now, with increasing technological development, using big data is becoming more and more popular, also in the glass processing industry, and it will surely become the next big thing.

As a growing number of machines become connected, the amount of data collected increases exponentially. And the huge amounts of data can be turned into valuable information with smart data analysis, enabling more efficient and profitable production processes. The more data collected, the more value it can provide for all connected machines.

In the hands of progressive glass processors, IoT can shape significant outcomes in the glass industry. These are the ones who dare to disrupt traditional operating processes by integrating innovative technologies before the rest.

Are you going to be the next progressive one to take advantage of IoT?

Für den Glastory-Newsletter anmelden

Wir beantworten Ihre Fragen zur Glasverarbeitung. Teilen Sie uns Ihre Herausforderungen mit und wir versprechen, unser Bestes zu tun, um Ihnen zu helfen.

Comments are closed.