Existing windshield production capacity has mostly been built from 1990 until early 2000. Yet the technology used now for modern windshields has dramatically changed since those days. A lot of development has gone into improving the process capability and efficiency of the production and bending equipment.

Let’s look at what are the reasons why and how to update a windshield bending process to match today’s needs.

Since the equipment has always been adapted to the maximum size of glass required at the time of investment, quite many furnaces are too small today. Striving for better driving comfort, fuel efficiency and safety have also affected car design, leading to a more aerodynamic contour and increased amount of glass.

Especially the height of the glass is bigger than ever. Some extreme examples of this trend are the new panorama windshields of the Citroen C3 Zenith, C4 Picasso, Opel Astra GTC and the new Tesla Model X. Further, the shape is more demanding and requires sophisticated molds and tools, which need more free space around them. All this increases the size of the mold space needed.

Glass shapes are getting more demanding all the time. Deeps sags with wrap-around corners are quite typical, requiring special tooling and perfect heat control. The modern bending process includes the use of all-around heating during the preheating and bending stages. The use of bottom heating is indispensable when bending flawless deep sags down to 20-35 mm or even more. Effective focusing, adjustability and power control are needed to bend the desired shape on a mold.

Modern tooling technology also includes double actuating molds, which require accurate triggering devices.

Heatable windshields are used for defogging and deicing during winter conditions. There are two ways to create them: using heating wires inside the laminate or a conductive coating on the inner surface of the glass. The use of coated solar control glass reduces the heat radiation inside the car, thus improving driving comfort in hot climates. It also reduces CO2 emissions as the air-conditioning device can have smaller dimensions.

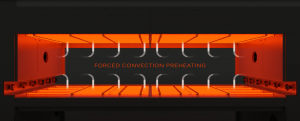

However, coating complicates the heating process in the furnace as the coating reflects the heat radiation from the heating elements. The best way to tackle the problem is to use forced convection. This will also contribute positively to your energy bill.

Glaston Matrix windshield bending furnace

The bending furnace is the most energy-intensive part of a windshield production process. Previous furnaces were typically either box furnaces or single-level furnaces. The double-level furnace with lightweight wagons was the first innovation to reduce the furnace’s energy consumption.

Currently, we have a lot of new features that can improve the energy efficiency of the equipment. Through design optimization, there is less mass to heat in the furnace. The use of forced convection further speeds up the heating and reduces wasted energy. Active heat recovery systems can also be applied.

For instance, a furnace with an annual output of half a million windshields consumes approximately 4.5 – 7 GWh a year depending on conditions. A reduction of 1.0 kWh per m² will cut your energy bill by more than EUR 70,000 annually!

Shape accuracy and process repeatability are increasingly important in modern bending equipment. Automatic assembling technologies set very tight tolerance requirements on the sag and form of a windshield, requiring precise control during the whole bending process. Moreover, the integrated functionalities of a windshield, typically such as head-up displays, set an ever-increasing demand for accuracy and repeatability.

The use of calibrated infrared pyrometers and intelligent fuzzy controls has been indispensable in achieving the desired shape when using sag, or gravity, furnaces.

Another important technology that helps achieve accuracy and repeatability is pressing. The new press-assisted systems are modular and can be added to even existing furnaces.

Convection technology has been the industry standard in all Low-E tempering facilities for years. It can also be used effectively to preheat windshields. The benefits of convection when processing coated glasses are clear, but convection provides the same benefits for clear glass as well. For instance, the dimensions of the furnace can be shorter. This means a lower initial investment, lower energy consumption, fewer wagons, each with less mold, as well as lower mold- and tooling-related costs.

Für den Glastory-Newsletter anmelden

Wir beantworten Ihre Fragen zur Glasverarbeitung. Teilen Sie uns Ihre Herausforderungen mit und wir versprechen, unser Bestes zu tun, um Ihnen zu helfen.

Comments are closed.